Motorcycle Parts New Zealand Specialists Fundamentals Explained

Table of ContentsMotorcycle Parts New Zealand Specialists Can Be Fun For AnyoneThe 7-Minute Rule for Motorcycle Parts New Zealand SpecialistsRumored Buzz on Motorcycle Parts New Zealand SpecialistsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutFascination About Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Can Be Fun For AnyoneThe Of Motorcycle Parts New Zealand SpecialistsA Biased View of Motorcycle Parts New Zealand Specialists

Get to out to one of our professionals today.CNC machining modern technology is quickly becoming the focal factor of several production processes around the world as a straight outcome of its lots of benefits over other methods. Furthermore, the markets that manufacture bikes have actually obtained on board with this fad. The most cutting-edge business are now developing their engine components and wheels utilizing machining techniques initially created for motorbike parts.

On the various other hand, the results of market are the main focus of this short article. Let's obtain right right into it. You may be questioning why we utilize. It is not tough to fathom the factors that led to this result. Since we have your interest allow us describe the reasoning behind this modern development in the motorbike manufacturing market.

All about Motorcycle Parts New Zealand Specialists

In enhancement, you have full control over the look of the components, even to the min information. Periodically, motorcyclists might determine to spruce up their experience by installing aftermarket elements or customizing the bike's remodeling. Once more, computer numerical control (CNC) machining is the most useful technique. Upgrades may be of any kind of type and design you want.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

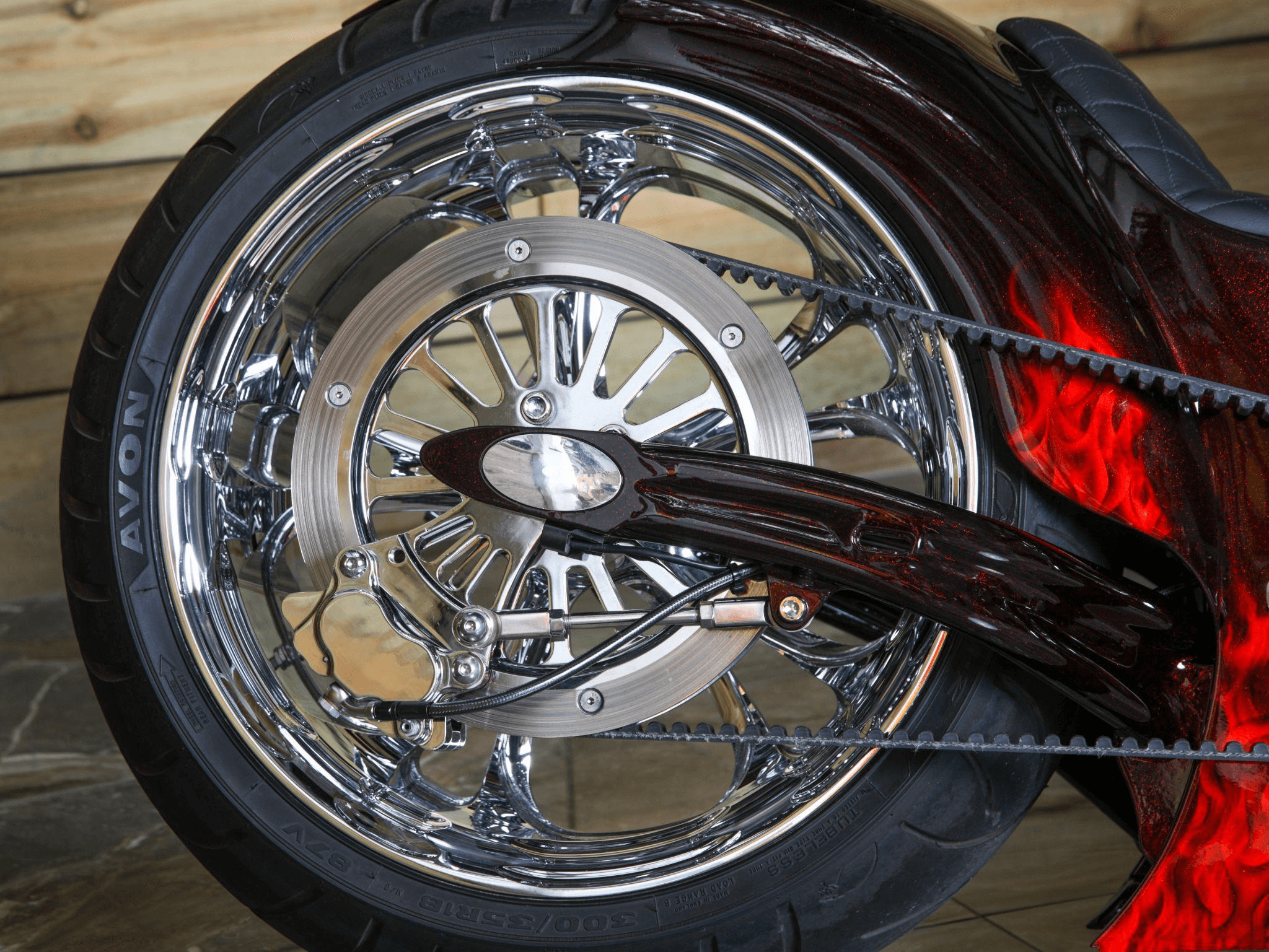

CNC machining may be made use of to make mostly all of a bike's steel and plastic parts. To proceed, we'll review numerous machined components for bikes. As opposed to those on vehicles, wheels on motorbikes often tend to be a lot more evident. Because of this, the bike's looks may be boosted with the suitable modification of these wheels.

Milling treatments are used to get the wanted degree of wheel customization. One more facet of the motorbike that might be individualized is the tires.

The Best Guide To Motorcycle Parts New Zealand Specialists

When it involves a lorry (or a motorbike), the most essential part is the engine. Numerous individuals mention it as the "heart" of the auto. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be elaborate and need designs with a high level of accuracy.

Usage just top quality products, nevertheless, considering that these lights are important for the safety and security of motorcyclists and other drivers or individuals on the road, particularly at evening. Motorcycle fronts lights have 3 major components: the light bulb, or light resource, the lens, and the real estate.

Milling procedures with a flawless coating would certainly cause the lenses having a reflective top quality that is comparable to that of a mirror. The cover, on the other hand, is not made up of breakable products; rather, it is created out of challenging polymers that can go be machined into more intricate patterns.

Our Motorcycle Parts New Zealand Specialists Ideas

Motorbike producers typically cast these elements, but only for the manufacturing of bespoke parts. Machining on five axes in today's world is the methods by which any type of layout form may be realized.

Choose Runsom for your tailored bike parts! We have the capacity to produce complicated and trendy elements making your bike matchless.

Right here are a few examples of steels typically utilized in bike component machining. Light weight aluminum is the key product used by companies specializing in generating customized motorcycle components to develop most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more metal that is very light in weight and has fantastic machining qualities due to its high mechanical toughness. This product might be created right into nearly any kind of form and keeps its measurements well. Also mission-critical elements that require a high level of accuracy may profit from their use.

A Biased View of Motorcycle Parts New Zealand Specialists

An additional steel that sees hefty use in the production of CNC-customized components is magnesium. It is amongst the lightest metals that are now accessible and has exceptional machinability attributes and stamina proportionate with its low weight. One of the disadvantages of magnesium is that its dirt might easily catch fire.

Their most common use in producing different motorcycle elements is bolts, such as screws and screws. Their low vulnerability to oxidation and corrosion makes them ideal for this use.

The Main Principles Of Motorcycle Parts New Zealand Specialists

It seems that CNC transforming and grating are the foundational processes. Different strategies exist, such as exploration. Let's examine most of these machining techniques comprehensive. The CNC transforming technique is taken into consideration a subtractive production method. In enhancement, it calls for keeping bars of material, usually plastic or metal, in setting and afterwards twisting a reducing tool to get rid of areas of the product as the product is transformed.

These approaches are similarly important and produce parts with high accuracy and constant top quality. They are respectively: grinding, laser cutting, and drilling. The term "surface finish" describes post-processes after the preliminary machining stage. Motorcycle see here Parts New Zealand Specialists. The processes assist boost the overall high quality of the machined motorbike components. Below are the quick introduction, pros and disadvantages of five surface therapy methods.

Get This Report about Motorcycle Parts New Zealand Specialists

Comments on “9 Easy Facts About Motorcycle Parts New Zealand Specialists Explained”